Welcome to our

site

Mould Flow Analysis

Gate location

Flow

Cool

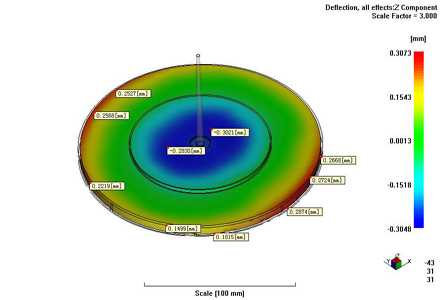

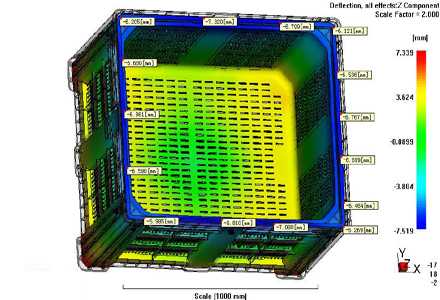

Warp

Runner balance

Stress analysis

Insert-molding

Double injection

Gas-assisted injection

Artmold Contact

Info:

Phone: 86-755-27794786

Fax: 86-755-22140028

E_mail:sales@artmold.com.cn

Address:TianQsingGe Building,XiXiang Town,BaoAn

District,ShenZhen City

__________________________________________

|

|

Warp Analysis

When looking critically at the causes of warpage, you could conclude that virtually any aspect of the molding process will have some effect on the warpage of the part. The four major categories that contribute to warpage are listed below:

Part design.

Mold design.

Processing conditions.

Material.

- Once you know that a part is going to warp outside the design criteria for that part, something will need to be changed with the part design, mold design, or processing to reduce the warpage.

Reducing warpage to within design criteria is critical for a successful part. The earlier this can be done in the product design cycle the better. Much of the time, reducing warpage involves changing the part design, however, changing the tooling design can also be an important component in reducing warpage. The cost of change is least when it is done early in the design cycle and will also mean less time to production.

|