|

Welcome to our

site

Mould Flow Analysis

Gate location

Flow

Cool

Warp

Runner balance

Stress analysis

Insert-molding

Overmolding

Gas-assisted injection

Artmold Contact

Info:

Phone: 86-755-27794786

Fax: 86-755-22140028

E_mail:sales@artmold.cn

Address:5D,B Block,West Industrial Building,XinAn Town,BaoAn

District,ShenZhen City

__________________________________________

|

|

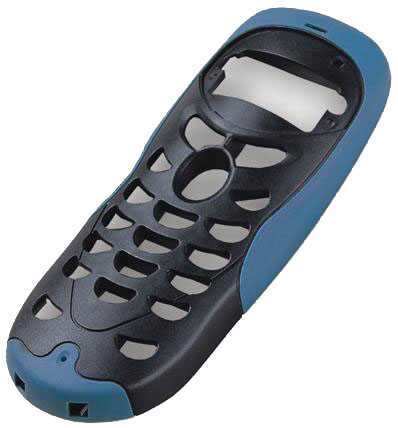

Overmolding

Overmolding is an injection molding process where two materials are molded together. Types of overmolding include two shot sequential overmolding, multi-shot injection molding or insert overmolding.

Multi-shot injection molding injects multiple materials into the cavity during the same molding cycle. Insert overmolding uses a pre-molded insert placed into the mold before injecting the second material. Two shot sequential overmolding is where the molding machine injects the first material into a closed cavity, and then moves the mold or cores to create a second cavity, using the first component as an insert for the second shot using a different material.

Materials are usually chosen specifically to bond together, using the heat from the injection of the second material to form that bond. This avoids the use of adhesives or assembly of the completed part. It can result in a robust multi-material part with a high quality finish.

When designing an overmolded part, wall thicknesses of both the insert and the overmolded component should be as uniform as possible to ensure an even and robust bond. Avoid ribs and sharp corners to reduce flow problems.

Overmolded parts take longer to cool than single shot injection molded part, and cooling systems are less effective. The insert acts as an insulator and heat is less efficiently extracted from the part. However, optimising the cooling system can help reduce the cycle time.

|